Strong Bonds Stronger Buildings

Premium Quality TMT Bars

Corrosion and seismic resistance

TMT bars that provide ultimate foundational support for constructions.

Applications

High rise buildings, residential buildings, industrial structures, nuclear power plant, airports & railways.

TMT FE 550D

Strong Bonds Stronger Buildings

Premium Quality TMT Bars

Corrosion and seismic resistance TMT bars that provide ultimate foundational support for constructions.

Applications

High rise buildings, residential buildings, industrial structures, nuclear power plant, airports & railways.

Meenakshi TMT bars have a flexible-pearlite core and a robust martensite external surface that makes the bar more weldable and ductile.

- Earthquake resistance

- Higher load absorption

- Unbreakable ductility

- Flexible TMT

- Higher elongation before breaking

Ductility

How we achieve this?

- Strict quality control measures

- Ensure lowest sulphur & phosphorus content

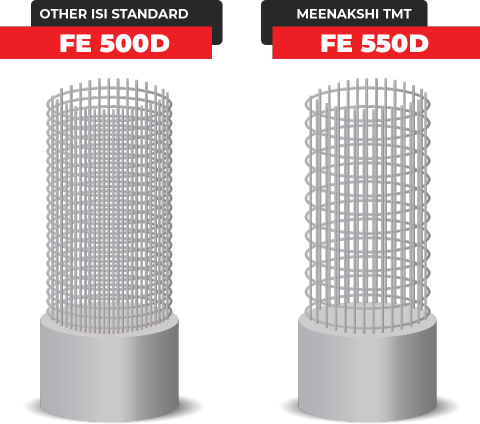

Why D is the best choice for all infrastructures?

- Higher bendability that helps bar-benders bend the rods

- Soft inner core

- Higher elongation before breaking

- Shock absorbent

- The flexibility that protects the infrastructure

The revolutionary Z Ribs Technology developed by Meenakshi TMT offers unmatched bonding with concrete and is proven to give long-lasting strength to all construction projects.

Meenakshi TMT bars have a flexible-pearlite core and a robust martensite external surface that makes the bar more weldable and ductile.

Strong foundational support

Save upto 15% on steel consumption by using lesser number of rebars

Lesser steel consumption helps in saving construction time

Easy loading unloading

Lesser storage space requirements

Easier transportation

Zero pilferages and theft

Standard bundle sizes

Labour friendly for loading and unloading the product

Digital test certificates

Rod size, lot number, mechanical & chemical composition

Quality control measures

Product USP's

Better Weldability

Superior Bonding Strength

Cost Effective

Better Weldability

Superior Bonding Strength

High load absorption capacity

Cost Effective

Unbreakable ductility

Earthquake resistant

High load absorption capacity

Unbreakable ductility

Earthquake resistant

PROPERTIES

PROPERTIES

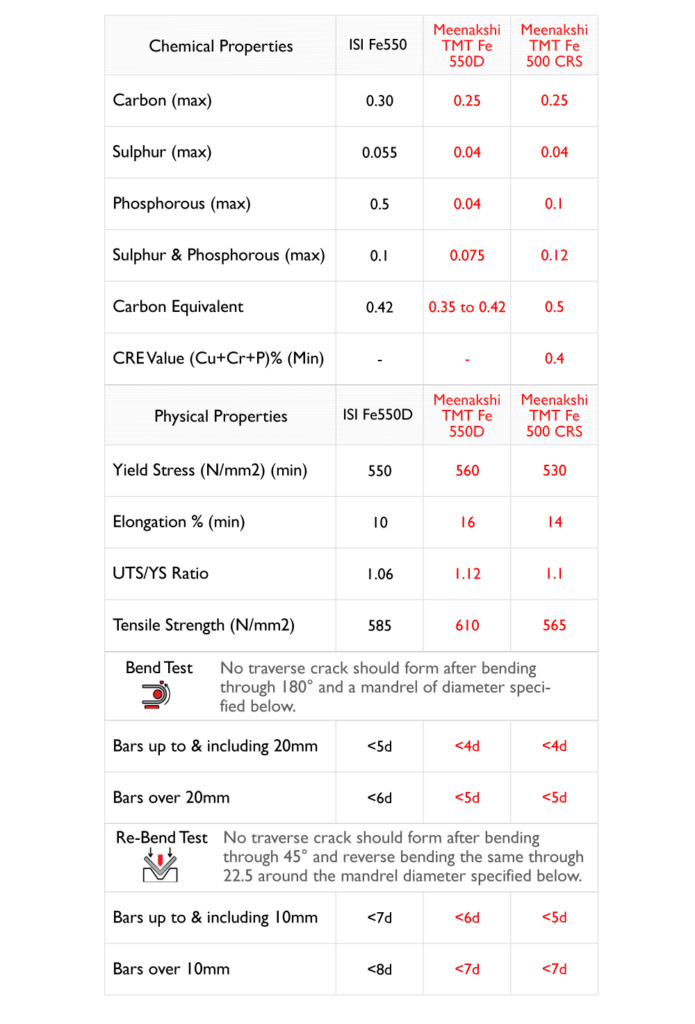

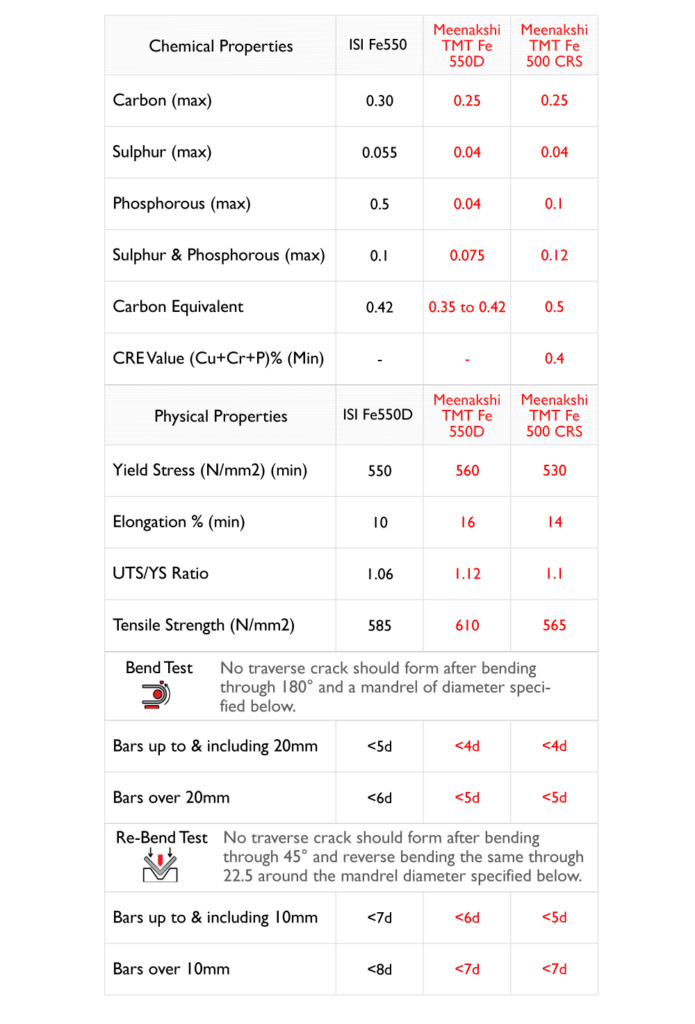

Chemical Properties

Carbon (max)

Sulphur (max)

Phosphorous (max)

Sulphur & Phosphorus (max)

Carbon Equivalent

CRE Value (Cu+Cr+P)%(Min)

ISI Fe550D

Meenakshi TMT FE 550D

Meenakshi TMT FE 500 CRS

Physical Properties

Yield Stress (N/mm2) (Min)

Elongation % (Min)

UTS/YS Ratio

Tensile Strength (N/mm2)

ISI Fe550D

Meenakshi TMT FE 550D

Meenakshi TMT FE 500 CRS

No traverse crack should form after bending through 180° and a mandrel of diameter specified below.

Bars up to and including 20mm

<5d

<4d

<4d

Bars over 20mm

<6d

<5d

<5d

No traverse crack should form after bending through 45° and reverse bending the same through 22.5 around the mandrel diameter specified below.

Bars up to and including 10mm

<7d

<6d

<5d

Bars over 10mm

<8d

<7d

<7d

Have questions? Check out our FAQ’s

Write to us and we will call you

Download our brochure for more information

Have any queries ?

Interested in becoming a dealer/distributor ?